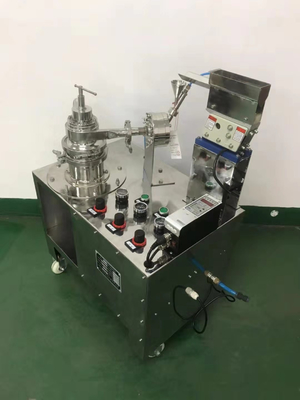

China Tencan Lab Jet Mill Graphite Micron Powder Mill Grinder Pulverizer

Product Details:

| Place of Origin: | China |

| Brand Name: | TENCAN |

| Certification: | CE&ISO |

| Model Number: | QLF-50 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1set |

|---|---|

| Price: | negotiable |

| Packaging Details: | Plywood case with foam |

| Delivery Time: | 7-14 working days after getting full payment |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 300sets/month |

|

Detail Information |

|||

| Product Name: | Lab Use Jet Mill Machine | Power Supply: | 380V/50HZ |

|---|---|---|---|

| Power: | 5.5KW | Designed Pressure: | 6.5-7kg/cm2 |

| Service Pressure: | 6.5-11kg/cm2 | Capacity: | 0.05-0.5kg/h |

| Feed Size: | 100-200mesh | Finess Of Output: | Less Than 5micron |

| Usage: | Water Treatment Chemicals,Coating Auxiliary Agents | Sample: | Available |

| Highlight: | 380V Lab Jet Mill,Graphite Lab Jet Mill,Micron Powder Mill Grinder |

||

Product Description

China Tencan Lab Jet Mill Graphite Micron Powder Mill Grinder Pulverizer

Introduction of Laboratory Classifying Jet Mill

Classifying jet mill is also called graded air flow pulverizer which has a wide range of adaptability for superfine pulverizing and grinding of various materials. It has good crushing performance especially for high hardness materials, brittle materials, coagulant and fibrous materials such as zircon sand, zirconia, silica, rutile titanium dioxide, alumina, talc, barium carbonate, barium sulfate, calcium carbonate, aluminum silicate, kaolin, carbon black, white carbon black, AC foaming agent, copying toner, coating, calcium hydrogen phosphate, bentonite, fluorescent powder, graphite, various fillers for plastics and rubber, pesticides, pearl powder, pollen, etc.

![]()

Working Priinciple of Laboratory Classifying Jet Mill

Powder material is sent to the feeding nozzle by the electromagnetic vibration feeder, and is injected into the pulverizing cavity by action of the feeding compressed air. The materials entering the pulverizing chamber and the high-speed air flow ejected by the pulverizing nozzle form a supersonic flow group, so that the materials collide and shear with each other in the pulverizing chamber and collide and rub with the wall of the pulverizing chamber, and finally achieve the purpose of pulverizing the materials into micron fine powder. In process of high-speed movement and material pulverizing, the particles with different fineness will produce different centrifugal forces in the rotating air flow. The powder particles with qualified fineness will be taken to the discharge pipe by exhaust flow because its centripetal air flow force is greater than centrifugal force, and then the finished powder will be collected by the cloth bag; The larger particles are thrown to the surroundings because its centrifugal force is greater than force of centripetal air flow, and are continuously crushed by continuous high-speed movement of the flow group.

Characteristics of Laboratory Classifying Jet Mill

The over-current components of the machine are made of corundum ceramic with high

hardness and high wear resistance. It has characteristics as following:

- Corrosion resistance, wear resistance, long service life, no pollution to materials.

- Strong superfine grinding ability and low energy consumption.

- Since it works under condition of lower temperature than normal room temperature, it is particularly suitable for low melting point and heat sensitive materials.

- It can pulverize more than two kinds of mixed materials.

- Compact structure, less land occupation, simple operation, convenient installation, disassembly and maintenance.

Technical Parameters of Laboratory Classifying Jet Mill

| Items | Technical Parameters |

| Product Name | Laboratory Classifying Jet Mill |

| Model No. | QLF-50 |

| Power Supply | 380V-50Hz |

| Power Comsumption | 5.5KW/hr |

| Designed Pressure | 6.5-7Kg/cm² |

| Service Pressure | 6.5-11Kg/cm² |

| Air Flow Volume | 0.6m³/min |

| Power Consumption | 5.5Kw/h |

| Capacity | 0.05-0.5Kg/h |

| Feed Size | 100-200 meshes |

| Fineness of Output | Average particle size < 5 μm |