Plant Small Laboratory Conical Ball Mill XMQ150*50 with 380V-50Hz Voltage and 0.75KW Power

Product Details:

| Place of Origin: | Hunan, China |

| Brand Name: | Tencan |

| Model Number: | XMQΦ150×50 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | USD1,650.00-$1,850.00/set |

| Packaging Details: | Plywood case |

| Delivery Time: | 15-25 working days |

| Supply Ability: | 350 sets per month |

|

Detail Information |

|||

| Product Name: | Conical Ball Mill | Model No.: | XMQΦ150×50 |

|---|---|---|---|

| Voltage: | 380V-50Hz, 3 Phase | Power: | 0.75KW |

| Max Capacity: | 0.2kgs | Feed Size: | Less Than 5mm |

| Output Particle Size: | 200 Meshes | Warranty: | One Year |

| Highlight: | Conical Laboratory Ball Mill,Plant Laboratory Ball Mill,Small Laboratory Ball Mill |

||

Product Description

1.

The lab-scale conical ball mill is a versatile grinding device designed for efficient sample processing in research and industrial applications. Featuring programmable operation durations, it supports both dry milling and liquid-based grinding techniques. Its advanced variable-frequency drive system offers broad speed adjustability for optimal processing control.

This compact unit combines user-friendly operation with effective grinding and blending capabilities, producing uniform particle distribution. The equipment operates quietly with minimal environmental impact, while its sealed design prevents sample contamination. Suitable for small-scale material testing, it serves laboratories, academic institutions, and industrial sectors including mineral processing, ceramics, and chemical analysis.

Engineered for reliability, the conical ball mill ensures rapid sample preparation with consistent results. It accommodates diverse materials, from metallic ores to brittle compounds, making it ideal for R&D and quality control. Additionally, its precision grinding extends to specialized industries such as pigments, pharmaceuticals, advanced ceramics, and composite materials, supporting ultrafine particle size reduction for specialized applications.

![]()

2,Working Principle of Lab Cone Ball Mill

The laboratory conical ball mill operates as a horizontal, rotating cylindrical grinding system powered by an external gear mechanism. This dual-chamber design efficiently processes materials through sequential grinding stages. Feed material is uniformly introduced into the primary chamber through an auger-equipped hollow shaft, where it encounters variably sized grinding media within a structured lining.

As the cylinder rotates, centrifugal motion propels the grinding balls upward before their controlled descent generates intense impact and abrasion forces, ensuring effective particle size reduction. Pre-processed material then transitions into the secondary chamber through a specialized partition. Here, a smooth lining configuration and optimized media arrangement facilitate fine grinding.

The final product exits through a precision discharge mechanism, achieving consistent particle size distribution. This staged grinding approach enhances processing efficiency while maintaining operational precision for diverse material types.

![]()

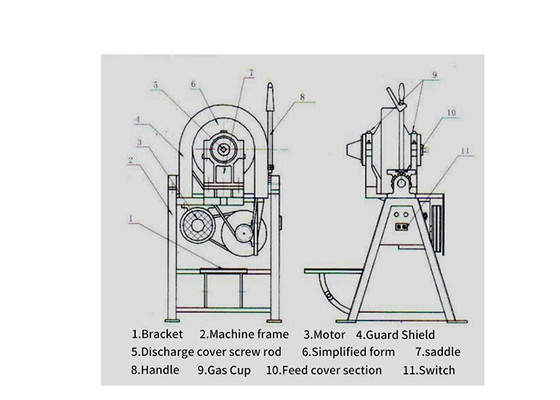

3,Structure Features of Lab Cone Ball Mill

The laboratory conical ball mill is constructed with precision-engineered components, ensuring efficient and reliable operation. Key structural elements include:

-

Material Handling System – A controlled feed mechanism and discharge outlet for seamless processing.

-

Rotary Assembly – A robust, balanced drum designed for consistent rotation.

-

Drive Mechanism – Comprising a high-efficiency motor, precision gear reducer, and responsive electronic controls for adjustable speed and torque.

The hollow shafts are fabricated from high-strength alloy steel, while the modular lining system allows for easy maintenance and customization. Critical wear components, such as the grinding chamber liners, are constructed from advanced abrasion-resistant materials to extend service life.

The gearing system is precision-machined for smooth power transfer, minimizing vibration and noise. With optimized mechanical stability and intelligent control integration, this mill delivers dependable performance for fine grinding applications.

![]()

4,Technical Parameters of Lab Cone Ball Mill

| Model | XMQΦ150×50 | XMQΦ240×90 | XMQΦ350×160 |

| Power Supply | 380V-50Hz 3 Phase | 380V-50Hz 3 Phase | 380V-50Hz 3 Phase |

| Power | 0.75KW | 1.1KW | 1.1KW |

| Max Capacity | 0.2KGS | 0.5-1.0KGS | 4.0KGS |

| Max Feed Size | ≤5mm | ≤5mm | ≤5mm |

| Output Particle Size | 200 meshes | 200 meshes | 200 meshes |

| Dimensions | 915*530*1160mm | 1052*640*1160mm | 700×575×1190mm |