Small Conical Laboratory Ball Mill For Mineral Sampling Preparation

Product Details:

| Place of Origin: | Hunan, China |

| Brand Name: | Tencan |

| Model Number: | XMQΦ240×90 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | USD2,180.00-$2,850.00/set |

| Packaging Details: | Plywood case |

| Delivery Time: | 15-25 working days |

| Payment Terms: | T/T |

| Supply Ability: | 220 sets per month |

|

Detail Information |

|||

| Product Name: | Cone Ball Mill | Model No.: | XMQΦ150×50 |

|---|---|---|---|

| Voltage: | 380V-50Hz, 3 Phase | Power: | 1.1KW |

| Max Capacity: | 1.0kgs | Feed Size: | Less Than 5mm |

| Output Particle Size: | 200 Meshes | Warranty: | One Year |

| Highlight: | Conical Laboratory Ball Mill,Small Laboratory Ball Mill,Mineral Sampling Laboratory Ball Mill |

||

Product Description

1.

The laboratory cone ball mill can freely set the operating time and can also be used for dry and wet grinding. It adopts frequency conversion technology and has a wide speed range. This machine is easy to grind and mix, uniform, easy to work and clean, with low noise and minimal pollution, and has good grinding and sealing performance. This model is a small, lightweight, and versatile laboratory grinding equipment that can be used in laboratories, research institutions, and ore beneficiation in industries such as metallurgy, petrochemicals, building materials, and coal mining. The conical ball mill has good performance, reasonable structure, high sample preparation efficiency, good sealing performance, and is suitable for crushing and processing various metal and non-metal ore raw material test samples. In addition, laboratory cone ball mills are suitable for ultrafine grinding in the coatings, ink, fuel, and food industries, as well as industries such as cement, silicate products, new building materials, refractory materials, fertilizers, black and non-ferrous metal beneficiation, and glass ceramics.

![]()

2,Working Principle of Lab Cone Ball Mill

The laboratory conical ball mill is a horizontal cylindrical rotating device driven by external gears, with two silos and a grid ball mill. The material enters the first chamber of the mill uniformly through the feeding hollow shaft screw from the feeding device. This chamber has a stepped or corrugated lining filled with steel balls of different sizes. The rotation of the cylinder generates centrifugal force, which brings the steel ball to a certain height and then drops it, causing strong impact and grinding on the material. After rough grinding in the first silo, the material enters the second silo through a single-layer partition. The second box is lined with a flat lining plate containing steel balls, where the material is further ground. The ground powder is discharged through the discharge grate to complete the grinding operation.

![]()

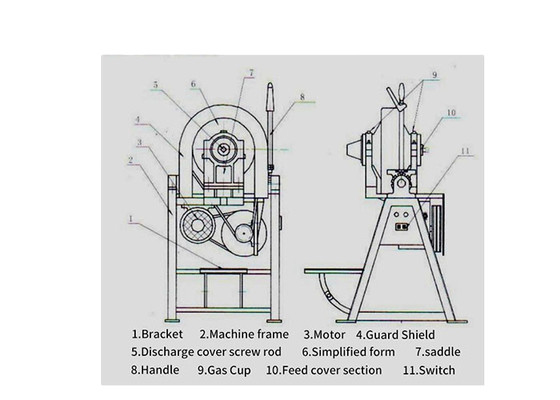

3,Structure Features of Lab Cone Ball Mill

This machine consists of main components such as feeding part, discharging part, rotating part, and transmission part (reducer, small transmission gear, motor, electric control). The hollow shaft is made of cast steel parts, and the lining can be disassembled and replaced. The large rotary gear is processed by casting and rolling, and the cylinder liner is made of wear-resistant lining plate, which has good wear resistance. The machine runs smoothly and has reliable performance.

![]()

4,Technical Parameters of Lab Cone Ball Mill

| Model | XMQΦ150×50 | XMQΦ240×90 | XMQΦ350×160 |

| Power Supply | 380V-50Hz 3 Phase | 380V-50Hz 3 Phase | 380V-50Hz 3 Phase |

| Power | 0.75KW | 1.1KW | 1.1KW |

| Max Capacity | 0.2KGS | 0.5-1.0KGS | 4.0KGS |

| Max Feed Size | ≤5mm | ≤5mm | ≤5mm |

| Output Particle Size | 200 meshes | 200 meshes | 200 meshes |

| Dimensions | 915*530*1160mm | 1052*640*1160mm | 700×575×1190mm |