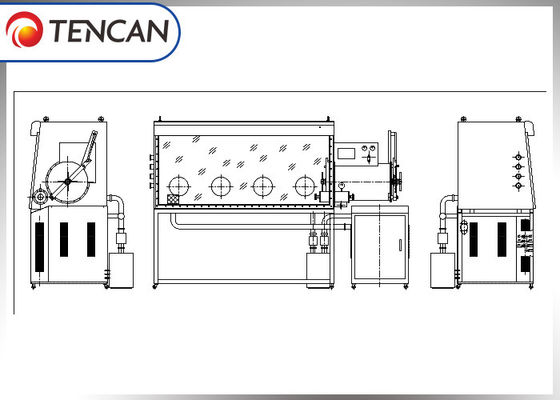

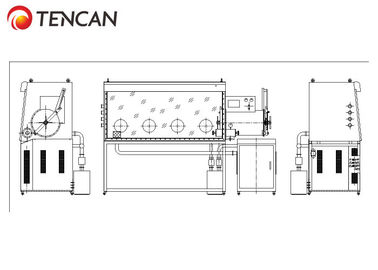

1900*1200*930mm Inert Gas Glove Box Double Sides with 8 Glove Ports

Product Details:

| Place of Origin: | Hunan, China |

| Brand Name: | TENCAN |

| Certification: | CE ISO |

| Model Number: | GBP1200D-8 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plywood Case+Foam |

| Delivery Time: | 25-35 working days After getting deposit |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 100 sets per month |

|

Detail Information |

|||

| Product Name: | Purification System Glove Box | Model No.: | GBP1200D-8 |

|---|---|---|---|

| Water Content: | Less Than 1PPM | Oxygen: | '-3000pa~+3000pa |

| Leakage Rate: | Less Than 0.05 Vol %/h | Bearing Pressure: | '-3000pa~+3000pa |

| Operating Side: | Single Sides | Purification Column: | Single Or Double At Buyer's Option |

| Highlight: | inert glove box,inert atmosphere glove box |

||

Product Description

1900*1200*930mm Inert Gas Purification Glove Box GBP1200D-8 Double Sides 8 Glove Ports With Double Purified Columns

Brief Introduction

Purification System Glove Box is a kind of laboratory device which can be filled with a high purity inert gas into the box and active substances can be filtered out of the box circularly. It is also called “vacuum glove box with water and oxygen removal”, and “inert gas purification glove box”. Main functions of this kind of glove box: water content removal, oxygen content removal, other organic gas removal. It is widely used for making high pure environment without water, oxygen and dust content.

Working principle

The box and purification system are connected together and they both form a well-sealed working environment. When inert gas or nitrogen is filled into the box continuously, the active substances inside the box shall be removed circularly out of the box to keep the inner box in a high cleanness and a high purity inert gas environment (water content≤1 ppm, oxygen content ≤1 ppm) all the time.

Structure Principle

Purification System Glove Box is mainly composed of two parts: a main box body and a transition chamber. We can also design and manufacture customized specifications according to the special requests of the clients.

The main box body has two (two or more) glove operation interfaces in front or back side of the box, which enables one or more people to operate the glove box at the same time, and improves much more efficiency of the glove box utilization. In addition, there are observation windows on the front or back side of the box where people can observe the operation process clearly inside the box. There are air suction and charging nozzles which can be used for air sucking or charging on the valves of the transition cabinet. The main box body is also installed with valve and nozzle, which can be used to maintain air pressure balanced inside the box body if necessary.

The transition cabinet is a transition space between main box body and outside, which is composed of two sealing doors, two valves and a chamber body. Both of the sealing doors can be used effectively to isolate the inner box of the main body from outside of box body. That enables people to send things in or out of the box freely under conditions that the box body is isolated from air atmosphere, avoiding many troubles of repeating evacuation and inflation.

Applications

Applies to making pure environment with removal of water, oxygen and dust.

R&D and production of battery industry (Lithium ion battery, powder battery, solar cell, lithium ion phosphate battery ).

R&D and manufacture of special lamp (HD lamp, metal halide lamp, ceramic metal halide lamp).

Welding (resistance welding, TIG welding, laser welding, plasma welding, brass solder)

R&D and production of OLED

R&D and production of pharmaceuticals

R&D and production of super capacitors

Fine chemical industry

Nuclear industry

R&D and production of new energy materials

Specifications

| Specifications of Standard Model of Purification Glove Box | ||||||

| No. | Model No. | Box Dimensions | Total Dimensions | Operating Sides |

Numbers of Gloves |

Options |

| 1 | GBP800S-2 | 1200*800*930mm | 1915*830*1830mm | Single | 2 | Single or double purification columns |

| 2 | GBP1000S-2 | 1200*1000*930mm | 1915*1060*1830mm | Single | 2 | Single or double purification columns |

| 3 | GBP1000D-4 | 1200*1000*930mm | 1915*1060*1830mm | Double | 4 | Single or double purification columns |

| 4 | GBP1200S-2 | 1200*1200*930mm | 1915*1260*1830mm | Single | 2 | Single or double purification columns |

| 5 | GBP1200D-4 | 1200*1200*930mm | 1915*1260*1830mm | Double | 4 | Single or double purification columns |

| 6 | GBP800S-3 | 1500*800*930mm | 2215*1060*1830mm | Single | 3 | Single or double purification columns |

| 7 | GBP1000S-3 | 1500*1000*930mm | 2215*1060*1830mm | Single | 3 | Single or double purification columns |

| 8 | GBP1000D-6 | 1500*1000*930mm | 2215*1060*1830mm | Double | 6 | Single or double purification columns |

| 9 | GBP1200S-3 | 1500*1200*930mm | 2215*1260*1830mm | Single | 3 | Single or double purification columns |

| 10 | GBP1200D-6 | 1500*1200*930mm | 2215*1260*1830mm | Double | 6 | Single or double purification columns |

| 11 | GBP800S-4 | 1900*800*930mm | 2615*1060*1830mm | Single | 4 | Single or double purification columns |

| 12 | GBP1000S-4 | 1900*1000*930mm | 2615*1060*1830mm | Single | 4 | Single or double purification columns |

| 13 | GBP1000D-8 | 1900*1000*930mm | 2615*1060*1830mm | Double | 8 | Single or double purification columns |

| 14 | GBP1200S-4 | 1900*1200*930mm | 2615*1260*1830mm | Single | 4 | Single or double purification columns |

| 15 | GBP1200D-8 | 1900*1200*930mm | 2615*1260*1830mm | Double | 8 | Single or double purification columns |

Notes:

Cabinet water and oxygen content under the standard condition:

Water content ≤1ppm, oxygen content≤1 ppm (Note: Standard condition is that an atmospheric pressure, constant temperature of 20 degree).

Leakage Rate: ≤0.05Vol%/ h (subject to change value of oxygen content in box)

Used Gas:

a) Working Gas: N2,Ar,He and etc.

b) Controlling Gas: Compressed air or Inert Gas.

C) Restoring Gas: Mixed gas of working gas and hydrogen.

Restoring gas is as same as working gas if there is only water removal system or oxygen removal system.

Remarks: All Single side boxes of 4 gloves are assembled glove box. Numbers of assembled box can be ordered as per customer’s needs. Quantity of purification columns is also designed to be matched according to customer’s requirements

Technical Parameters

| TECHNICAL DATA OF TENCAN INERT GAS GLOVE BOX WITH PURIFICATION SYSTEM | |

| Items | Data |

| Water content under the standard condition (Note: The standard condition is one atmospheric pressure, constant temperature of 20 degrees) | ≤1ppm |

| Oxygen content under the standard condition (The standard condition is one atmospheric pressure, constant temperature of 20 degrees ) | ≤1ppm |

| Max Vacuum Degree which the transition cabinet bears | <100pa |

| Leakage Rate | ≤ 0.05vol%/h |

| Gas presure range inside the box | -3000pa~+3000pa |

Functions

| FUNCTIONS OF TENCAN INERT GAS GLOVE BOX WITH PURIFICATION SYSTEM | |

| Items | Descriptions |

| Automatic Control | Controlled and monitored automatically by the program control unit. |

| Box body gas replacement (manual/automatic) |

Before initial use, cabinet air shall be replaced with inert gas or nitrogen, which can be easily achieved by using auto gas replacement function of the cabinet provided by the system, gas replacement can also be achieved manually. |

| Transition cabinet replacement (manual/automatic |

When material was placed in a box, the transition cabinet of the gas needs to be replaced. You may automatic gas exchange function provided by the airlock system; you may also achieve gas replacement manually. |

| Gas purification control | After setting up the work status and results, the system purification procedures set to “Auto”, the system will automatically maintain the atmosphere condition of the cabinet,then the system will automatically complete the work; you may also choose manual control. |

| Pedal air-pressure control | Use the foot controller-through inflation or exhaust system, to control gas pressure in the cabinet. |

| Reduction of purification system | Purification materials reduction is done automatically by the system, we only need to set the conditions of system reduction. Open “reduce”, the system will automatically complete reduction, the whole process does not need to monitor. |

| On-line operating condition detection | The control system provides users with the operating condition detection function of the component of the equipment. Such function can be used to observe operating condition of the component and inspect fault source of each function and component. |

| System parameter setting | System settings function, users can set the system parameters to achieve the desired working conditions and feature set. |

| Data logging function | The system provides operating parameter record of the equipment, this record can be traced back to monitor production or experiment. |

| Control of gas reserve function | When the temporary cutting of control-gas supply, or cutting off control-gas source for some time, the control-gas reserve will protect the equipment continue working. |

| Standby function of cycle gas cooled | Purification system provides a heat exchange for cooling the circulating gas, can be used alone by injecting the coolant to control the temperature of the circulating gas. |

| Multi-level safety system | The control system sets up a variety of security features, include multilevel security tips, alarm and disable function, to protect the safety of operating personnel and equipment. |

| Protection function when purification cycle blocked |

When the circulation system is blocked, the control system prompts alerts, and take the initiative to adjust the speed of air, in order to protect the motor, though this function can also check out system cycle blocked, pipeline poor, filter control dust obstruction, and other issues. |

![]()

![]()