200-3000 KGS/Hour Powder Jaw Crusher Machine Uniform Output 10mm

Product Details:

| Place of Origin: | Hunan, China |

| Brand Name: | TENCAN |

| Certification: | CE |

| Model Number: | PE60*100 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plywood Case |

| Delivery Time: | 15-25 working days after getting full payment. |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 200 sets per month |

|

Detail Information |

|||

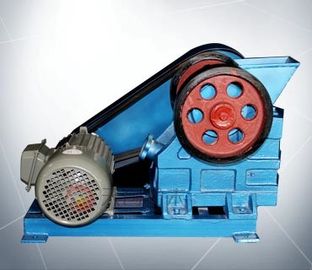

| Product Bane: | Lab Jaw Crusher | Model No.: | PE100*60 |

|---|---|---|---|

| Color: | Blue Or Green | Voltage: | 380V-50Hz |

| Power: | 1.5KW | Feed Size: | Less Than 50mm |

| Output Size: | 6-10mm | Capacity: | 230-400kgs/hour |

| Highlight: | 10mm Jaw Crusher Machine,Powder Jaw Crusher Machine,3000 KGS/Hour Powder Crusher Machine |

||

Product Description

China Tencan 200-3000KGS/Hour 380V Uniform Output Powder Lab Jaw Crusher Machine With Stable Operation

Overview of Lab Jaw Crusher

Lab jaw crusher is mainly used to crush a variety of ores and bulk materials with comprehensive strength of less than 320Mpa in middle granularity. PE series of lab jaw crusher has full specification, its feed size of materials ranges 125mm~1200mm, and it is the preferred primary crushing equipment. The equipment is mainly applied to crush materials in rough, medium and fine scale such as ore limestone, calcium carbide, carbide slag, shale, basalt , river gravel, blue stone, etc. The machine has a significant performance in cement plants, gravel plants, stones factory, thermal power plants desulfurization, calcium carbide plant, and it is widely used in mining metallurgy, chemical industry, building materials, water conservancy, transportation and other industries.![]()

Working Principle of Lab Jaw Crusher

Applications of Lab Jaw Crusher

Jaw Crusher is mainly used for crushing large bulk mineral materials into small pieces so as to finely grind by ball mill. It is widely used to crush all kinds of ores and bulk material. The equipment mainly applied to crush materials in rough, medium and fine scale such as ore limestone, calcium carbides, carbide slag, shale, basalt, river gravel, blue stone etc.

Features of Lab Jaw Crusher

1. The crusher ratio can reach to about 13 in uniform size;

2. Adopt gasketed nesting population adjustment device,the adjusting range is big and reliable operation;

3. High efficiency,low energy consumption,compared with common small jaw crusher,it’s processing capacity 20%-35% higher than that of the same specification,and can reduce the energy consumption of 15%-20%;

4. Deep crushing chamber has no dead zone and can increase the feed ability and production capacity;

5. The use of small wear hyperboloid jaw plate service life can be prolonged by more than 3-4 times in the same process conditions,especially to the high abrasive material is more obvious;

6. The lubrication system is safe and reliable, convenient replacement parts, maintenance workload is small.

Technical Parameters of Lab Jaw Crusher

| Parameters of Lab Jaw Crusher | |||||||

| Model No. | Capacity (Kgs/h) | Inlet Size (mm) | Feed Size (mm) | Output Size (mm) | Spindle Speed (rpm) | Power Supply | Net Weight (KGS) |

| XPC100*60 | 230-400 | 100*60 | ≤50 | 6.0-10.0 | 650 | 380V/1.5KW | 350 |

| XPC100*100 | 200-1800 | 100*100 | ≤80 | 3.0-25.0 | 600 | 380V/2.4KW | 300 |

| XPC125*100 | 200-1800 | 125*100 | ≤80 | 5.0-25.0 | 500 | 380V/3.0KW | 300 |

| XPC100*150 | 200-1800 | 100*150 | ≤90 | 6.0-38.0 | 500 | 380V/2.2KW | 360 |

| XPC150*125 | 400-3000 | 150*125 | ≤100 | 6.0-38.0 | 500 | 380V/3.0KW | 417 |

| PEF150*250 | 700-1500 | 150*250 | ≤120 | 6.0-40.0 | 350 | 380V/5.5KW | 500 |

| PEF60*100 | 45-550 | 60*100 | ≤50 | 1.0-10.0 | 290 | 380V/1.5KW | 110 |

| PEF100*100 | 65-850 | 100*100 | ≤80 | 1.0-25.0 | 600 | 380V/2.2KW | 320 |

| PEF100*125 | 300-2000 | 100*125 | ≤100 | 2.0-35.0 | 375 | 380V/3.0KW | 360 |

| PEF150*125 | 300-3000 | 150*125 | ≤120 | 4.0-45.0 | 375 | 380V/3.0KW | 380 |

![]()