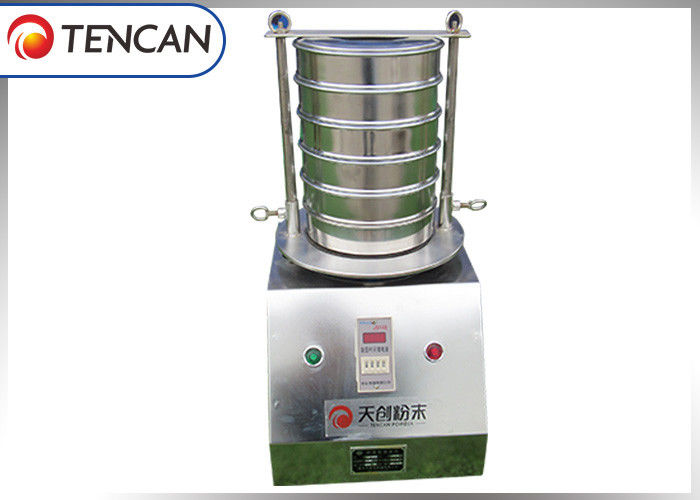

220V 0.15KW Powder Sieving Machine Laboratory Scale CE / ISO Approval

Product Details:

| Place of Origin: | Hunan, China |

| Brand Name: | TENCAN |

| Certification: | CE ISO |

| Model Number: | BZS-200 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plywood Case + Foam |

| Delivery Time: | 3-7 working days after getting full payment |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 200sets per month |

|

Detail Information |

|||

| Name Of Product: | Lab Sieving Shaker Machine | Material: | Stainless Steel |

|---|---|---|---|

| Available Sizes Of Screen: | 5-350 Mehses | Max Layers: | 6-8 Layers |

| Shaking Frequency: | 1400 Times Per Min | Power Supply: | 220V/0.15KW |

| Net Weight: | 30-40 Kgs | Dimensions: | 320*350*360mm |

| Highlight: | sieve shaker machine,powder screening equipment |

||

Product Description

BZS-200 Stainless Steel Electric Lab Sieve Shaker machine For Nano Powder Sieving

Overview

Lab sieving shaker machine, also known as vibrating sieve shaker, is a kind of lab equipment which is used for testing powder particle size and granularity analysis in replacement of manual sieving. Lab sieving shaker machine is widely applied in food, medicine, metallurgy, building materials, chemical industry, cement, glass, grain, ceramics, paper industry and other materials. It can be used for dry and wet sieving, filtering. This equipment has advantages of smooth vibrating, large exciting force, stable performance, fast replacing sieve screen, light weight, simple operation and easy maintenance. The basic working principle is to change the motor's rotation movement into three dimensional movement of horizontal, vertical and inclined, and then transfer movement to the sieve screen. If changing the phase angle of the hammer at the top and bottom, direction of the raw material shall be changed accordingly.

![]()

Applications: Lab sieving shaker machine is a kind of new type equipment which can be used for sieving all kinds of powder particles in high efficiency. It is widely applied to in many industries of minerals, building materials, communication, chemicals, and etc.

Working Principle

Lab sieving shaker machine is composed of screen box, screen net, vibrator, damping spring device, and foundation. Vibrator is on the side plate of screen box together with motor, which drives the vibrator to rotate by coupling or belt. Centrifugal inertia force makes the screen box vibrate. Screen is the main wearing parts. High manganese steel mesh, perforated screen plate and rubber screen plate can be selected according to materials as well as requirements of users. Screen plate has two kinds: single layer and double layer. Each one can meet sieving effects of different requests. All screens are installed on foundation, Dip angle of screen can be adjusted by changing spring pedestal.

Features

1, Sieving screen can be quickly replaced without any tools, and the number of layers can be reached to 7-8 layers.

2, It is installed with automatic control timer which can be set for 1-60 minutes.

3. It can be used for sieving any powder, liquid and granular.

4, when working, powder is not flying, liquid is not sprayed, and granular does not jump.

5, Full sizes of screen hole are available from 3.5 meshes to 400 meshes.

Parameters

| Parameters of Lab Sieving Shaker Machine | ||

| Name | Normal Lab Sieve Shaker | Stainless Steel Lab Sieve Shaker |

| Model No. | ZS-200 | BZS-200 |

| Diameter of Sieve Screen(mm) | 5-350 meshes | 5-350 meshes |

| Max Layers | 6 | 8 |

| Shaking Frequency | 1400 tpm | 1400 tpm |

| Voltage | 220V | 220V |

| Power | 150W | 150W |

| Dimensions | 320*350*360mm | 320*350*360mm |

| Net Weight | 30kgs | 40kgs |