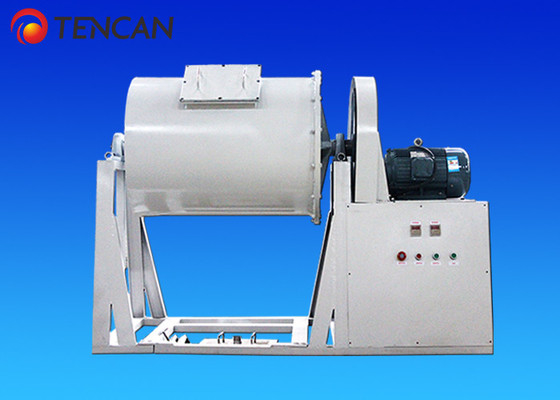

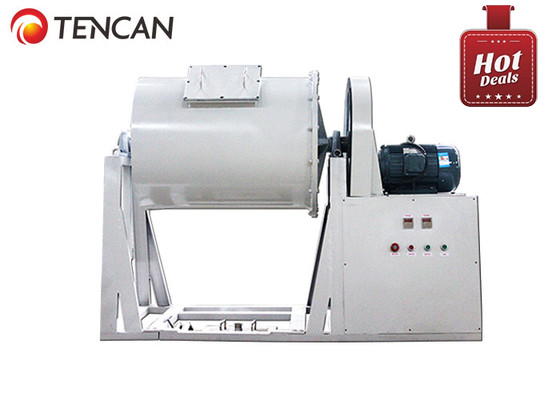

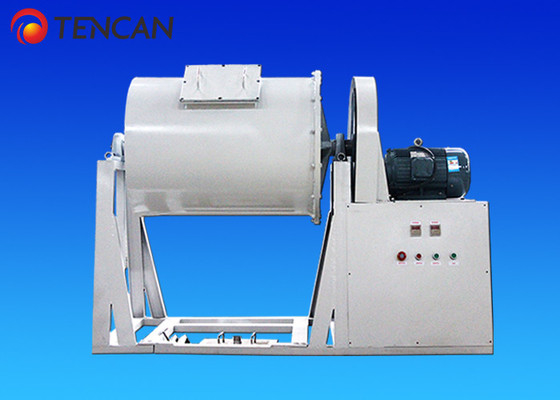

Ceramic Liner 500L Rolling Ball Mill Heavy Type Low Noise 7.5KW

Product Details:

| Place of Origin: | Hunan, China |

| Brand Name: | TENCAN |

| Certification: | CE ISO |

| Model Number: | QM-500 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plywood Case+Foam |

| Delivery Time: | 20-35working days after getting full payment |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 220 sets per month |

|

Detail Information |

|||

| Product Name: | Heavy Type Roll Ball Mill | Model No.: | QM-500 |

|---|---|---|---|

| Voltage: | 380V-50Hz | Power: | 7.5KW |

| Rotation Speed: | 20-36 RPM | Speed Control: | Frequency Control |

| Total Volume: | 500L | Max Capacity: | 175L |

| Highlight: | Ceramic Liner Rolling Ball Mill,500L Heavy Duty Ball Mill,Low Noise 7.5KW Ball Mill |

||

Product Description

Ceramic Liner 500L Rolling Ball Mill Heavy Type Low Noise 7.5KW

Overview

**Technical Features**

1. Reliable operation with high efficiency, low noise emission and contamination-free processing

2. Compatible with various rigid materials through dry or wet grinding modes, suitable for both coarse and fine grinding as well as material mixing

3. Integrated automatic pouring system with built-in grinding media separation for convenient powder discharge

4. Complete safety enclosure ensures maximum purity and zero contamination during operation

5. Exceptional wear resistance with optimized grinding efficiency

6. Multiple liner materials available including alloy steel, stainless steel, wear-resistant polyurethane, alumina ceramic, and zirconia, with capacity options ranging from 20L to 2000L

**Model Selection Guide**

1. Model designation follows QM-(Capacity)-(A: adjustable speed, B: standard version) format. Example: QM-50-A indicates 50L roller mill with speed adjustment

2. Suitable model selection should be based on processing material quantity (by weight)

3. Optimal jar and ball materials should be selected according to material characteristics

4. Optional accessories include automatic pouring mechanism and dust-proof enclosure

5. Quick-change jar design accommodates both wet and dry grinding applications with easy material switching

**Product Advantages**

- Advanced drive system ensures stable operation with minimal maintenance

- Flexible configuration options meet diverse laboratory and production requirements

- Intelligent separation system streamlines material handling process

- Comprehensive safety features guarantee operator protection and sample purity

- Modular design supports customized solutions for specialized applications

Technical Parameters

| Technical Parameters OF HeavyType Roll Ball Mill | ||||||||

| Model | Volume Size (L) |

Rotating Speed (rpm) |

Max Capacity (L) |

Power Supply | Available Jars | Feed Size (mm) |

Output Granularity (mesh) |

Adjusted Mode of Rotate Speed |

| QM-200L | 200 | 20~40 | 70 | 380V/3.7KW | carbon steel stainless steel, lining,replaceable,nylon polyurethane,PTFE,corundum and etc |

≦10 | ≧300 | frequency converter speed or fixed speed |

| QM-300L | 300 | 20~38 | 105 | 380V/5.5KW | ≦10 | ≧300 | ||

| QM-500L | 500 | 20~36 | 175 | 380V/7.5KW | ≦10 | ≧300 | ||

| QM-1000L | 1000 | 20~34 | 350 | 380V/11KW | ≦20 | ≧300 | ||

| QM-2000L | 2000 | 20~34 | 700 | 380V/22KW | ≦20 | ≧300 | ||

Accessories of Light Roll Ball Mill

Besides light roll ball mill machine, our factory provides all kinds of roll mill pots,like stainless steel mill pot, zirconia mill pot, alumina mill pot, nylon mill pot, PU mill pot, tungsten mill pot, normal ceramic mill pot and etc.

![]()

| Recommendation For Matching Solutions About Mill Jars & Materials | |

| Categories of Materials | Recommended Mill Jars |

| Soil and other Materials which are not allowed with any impurity | Agate mill jar |

| Metal & nonmetal materials which are not allowed with any impurity | Zirconia mill jar |

| High hardness materials like diamond, tungsten carbide | Tungsten carbide mill jar |

| Strong add & alkali materials or other materials at high temperature | PTFE mill jar |

| Iron ore materials with lower impurity sensitivity | 304 Stainless steel mill jar |

| Pigment or other materials with later process under high temperature | Nylon mill jar |

| Aluminum materials like ceramic glaze | Corundum mill jar |

| Electronic materials like lithium battery | Polyurethane mill jar |

| Easily oxidized materials or some special materials which need to be protected under special atmosphere. |

Vacuum mill jar |

We can also provide all kinds of mill balls like stainless steel balls, zirconia balls, alumina balls, tungsten carbide balls, agate balls, hard metal balls, silicon nitride balls, high wear resistant steel ball, manganese steel balls, and other special metal materials.

![]()

| References About Grinding Medias & Materials | ||

| Materials of Grinding Media |

Hardness (Mohs) |

Features |

| Zirconia Balls | ≥9.0 | Super wear-resistance, without any impurity, corrosion & high temperature resistance. |

| Stainless Steel Balls | ≥6.0 | Wear-resistant, general corrsion resistance, high temperature resistance. |

| Agate Balls | ≥7.0 | Super wear-resistance, used for medicine,food and other materials which can not be contaminated with metal, corrosion, and high temperature resistance. |

| Alumina Balls | ≥8.5 | Wear-resistant, corrsion resistance and high temperature resistance. |

| Tungsten Carbide Balls | ≥9.0 | Super wear-resistance, without any impurity, corrosion & high temperature resistance. |

| Matching Solutions for Mill Jars & Balls | |||||

| Items | Agate Balls | Alumina Balls | Stainless Steel Balls | Zirconia Balls | Tungsten Carbide Balls |

| Agate Mill jar | √ | ||||

| Corundum Mill Jar | ▲ | √ | ▲ | ||

| Stainless Steel Mill Jar | √ | ||||

| Zirconia Mill Jar | ▲ | √ | |||

| Nylon Mill Jar | ▲ | √ | |||

| PTFE Mill Jar | √ | ▲ | |||

| Polyurethane Mill Jar | √ | ▲ | |||

| Tungsten Carbide Mill Jar | ▲ | √ | |||

| √ means: most suitable ▲ means: suitable | |||||