Industrial 100L V-Type Powder Mixer for Fertilizer & Agricultural Chemicals Blending

Product Details:

| Place of Origin: | Hunan, China |

| Brand Name: | TENCAN |

| Certification: | CE ISO |

| Model Number: | V-100L |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plywood Case+ Foam |

| Delivery Time: | 20-30 working days after getting full payment |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 100 sets per month |

|

Detail Information |

|||

| Specifications: | 100L | Material: | 304 Stainless Steel |

|---|---|---|---|

| Color: | White Or Grey | Packing: | Plywood Case+Foam |

| Voltage: | 220V Or 380V | Type: | Mixing Machine |

| Place Of Origin: | Hunan, China | Certificate: | CE ISO |

| Highlight: | Agricultural Chemicals Powder Mixer,100L V-Type Powder Mixer,Powder Mixer for Fertilizer |

||

Product Description

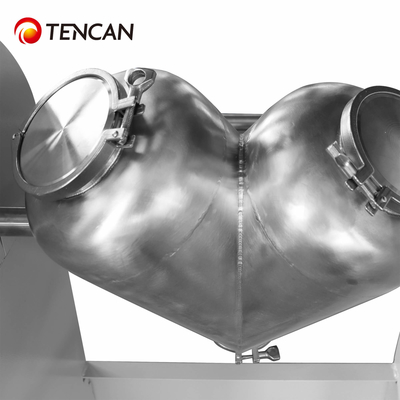

Industrial 100L V-Type Powder Mixer for Fertilizer & Agricultural Chemicals Blending

Overview

The V-type powder mixing machine is designed for efficient dry powder and granule blending across pharmaceutical, food, chemical, metallurgical, and electronic industries. Featuring a manual loading system and sealed butterfly valve discharge, the equipment ensures dust-free operation while maintaining material purity. Its distinctive asymmetrical cylinder design delivers high-efficiency mixing with complete material turnover and zero dead zones. Constructed with premium stainless steel and featuring fully polished contact surfaces, the mixer prevents material contamination while achieving uniform blending. The system can be customized with optional forced mixing attachments to handle challenging materials including fine powders, semi-wet aggregates, and small particulates.

Working Principle

The V-type mixer operates through a precisely engineered dual-cylinder chamber with asymmetric geometry. During rotation, the intersecting cylinders create a three-dimensional tumbling action that continuously divides and recombines materials. This dynamic motion produces cascading particle flow patterns, ensuring thorough dispersion as materials transfer between chambers. The optimized vessel geometry generates simultaneous axial and radial movement, achieving perfect powder stratification and surface distribution without mechanical agitation.

Features

1. Precision Blending Performance - Achieves homogeneous mixing for materials with similar particle size and density profiles

2. Gentle Material Handling - Specialized motion preserves granule integrity without crushing or excessive abrasion

3. Advanced Surface Engineering - Mirror-polished interior/exterior surfaces eliminate contamination risks and residual accumulation

4. Material Versatility - Available in 304/316L stainless steel, carbon steel, or food-grade nylon constructions

5. Intelligent Process Control - Programmable timer with auto-shutoff enables precise batch processing

6. Hybrid Mixing Capability - Optional high-shear agitator compatible for challenging powder formulations

7. Sanitary Design - Fully disassemblable structure meets cGMP requirements for pharmaceutical applications

8. Energy-Efficient Operation - Optimized rotation mechanics reduce power consumption by 25% versus conventional mixers

Parameters

| Parameters of V Type Mixing Machine | |||||

| Model No. | Mixing Volume (L) |

Total Volume (L) |

Feed Volume Coefficient |

Power (KW) |

Rotating Speed (rpm) |

| V-5 | 2 | 5 | 0.4 | 0.25 | 50 |

| V-10 | 4 | 10 | 0.4 | 0.25 | 45 |

| V-20 | 8 | 20 | 0.4 | 0.37 | 32 |

| V-50 | 20 | 50 | 0.4 | 0.75 | 32 |

| V-100 | 40 | 100 | 0.4 | 1.5 | 30 |

| V-200 | 80 | 200 | 0.4 | 3 | 24 |

| V-300 | 120 | 300 | 0.4 | 4 | 20 |

| V-500 | 200 | 500 | 0.4 | 7.5 | 12 |

![]()

![]()

chemical powder mixing machine

small powder mixer machine