Tencan ZM-20L Light Vibrating Ball Mill with Frequency Converter Ceramic / Zirconia / PTFE Liners

Product Details:

| Place of Origin: | Hunan, China |

| Brand Name: | TENCAN |

| Certification: | CE |

| Model Number: | ZM-20 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plywood Case + Foam |

| Delivery Time: | 20-30 working days after getting full payment. |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 100 sets per month |

|

Detail Information |

|||

| Product Name: | Light Type Vibration Ball Mill | Model No.: | ZM-20 |

|---|---|---|---|

| Voltage: | 380V | Power: | 1.5KW |

| Vinration Frequency: | 1440 Rpm | Speed Control: | Frequency Control |

| Total Volume: | 20L | Max Capacity: | 10L |

| Highlight: | Frequency Converter Vibrating Ball Mill,20L Light Vibrating Ball Mill,Zirconia Vibrating Ball Mill |

||

Product Description

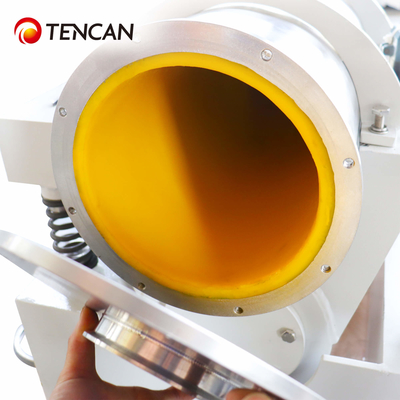

20L Light Vibrating Ball Mill With Frequency Converter And Ceramic, Zirconia & PTFE Liners

Overview

The light type vibrating ball mill, also referred to as vibration mill, represents an innovative generation of high-efficiency powder processing equipment. Available in three configurations - single cylinder, double cylinders, and three cylinders - this compact milling solution combines exceptional performance with user-friendly operation. The laboratory vibrating ball mill delivers reliable processing capabilities, requires minimal maintenance, demonstrates excellent environmental compatibility (zero pollution emissions), and supports both dry and wet grinding applications. Customers may select from multiple cylinder liner options including: food-grade 304/316L stainless steel, high-purity alumina ceramic (corundum), yttria-stabilized zirconium oxide, as well as engineering polymers (nylon, polyurethane, PTFE, PP, PE).

Working Principle

The light type vibrating ball mill's optimized mechanical system comprises a reinforced frame, precision-engineered chassis, high-performance vibration exciter, grinding cylinder assembly, damping springs, and energy-efficient motor. Upon activation, the motor transmits power to the vibration generator, creating controlled high-frequency oscillations (typically 1000-3600 vibrations per minute) with precisely regulated amplitude (0.5-5mm). This motion induces intensive multi-directional movement of grinding media, facilitating:

Continuous high-velocity impacts

Efficient surface abrasion

Homogeneous particle size reduction

Resulting in superior grinding efficiency and uniform product fineness.

Applications

This versatile light-type vibration mill serves diverse industrial and research applications:

Electronics Manufacturing: Dielectric ceramics, ferrite cores, conductive pastes

Advanced Materials: Nanocomposites, quantum dots, battery materials

Chemical Processing: Catalysts, inorganic pigments, polymer additives

Powder Metallurgy: Tungsten alloys, carbide powders, metal matrix composites

Pharmaceuticals: API micronization, controlled-release formulations

Specialty Products: Magnetic materials, rubber compounds, radio-frequency components

Features

1, It has larger capacity compared with other ball mills.

2, Simple structure, by adjusting the amplitude, frequency, media. Different ratio produces different particle size.

3. The vibrating ball mill with a jacket tube can adjust grinding temperature.

4. The vibrating ball mill with sieve and collecting devices keeps production continuously.

5, Simple and convenient operation, reliable work, easy cleaning, strong adaptability to working conditions.

6, No environmental pollution, dry and wet ball milling can be carried out.

7, Light weight, small volume, high efficiency.

8. Special order can be made according to the requirements.

Technical Parameters of Tencan Light Type Vibrating Ball Mill

| Technical Parameters of Light Type Vibrating Ball Mill | ||||||

| Model No. |

Total Volume |

Max Load Volume | Power Supply | Available Barrel | Feed Size | Output Granularity |

| ZM-10 | 10L | 5L | 380V/1.5KW | Can be lined with: Polyurethane Nylon Alumina ceramic Zirconia PTFE |

≤10mm | ≤1μm |

| ZM-15 | 15L | 7.5L | 380V/1.5KW | ≤10mm | ≤1μm | |

| ZM-20 | 20L | 10L | 380V/1.5KW | ≤10mm | ≤1μm | |

Available Mill Jars: Stainless steel mill jar, alumina ceramic mill jar, Zirconia mill jar, agate mill jar, tungsten carbide mill jar, PU mill jar, nylon mill jar, PTFE mill jar, and etc.

![]()

| Recommendation For Matching Solutions About Mill Jars & Materials | |

| Categories of Materials | Recommended Mill Jars |

| Soil and other Materials which are not allowed with any impurity | Agate mill jar |

| Metal & nonmetal materials which are not allowed with any impurity | Zirconia mill jar |

| High hardness materials like diamond, tungsten carbide | Tungsten carbide mill jar |

| Strong add & alkali materials or other materials at high temperature | PTFE mill jar |

| Iron ore materials with lower impurity sensitivity | 304 Stainless steel mill jar |

| Pigment or other materials with later process under high temperature | Nylon mill jar |

| Aluminum materials like ceramic glaze | Corundum mill jar |

| Electronic materials like lithium battery | Polyurethane mill jar |

| Easily oxidized materials or some special materials which need to be protected under special atmosphere. |

Vacuum mill jar |

| References About Grinding Medias & Materials | ||

| Materials of Grinding Media |

Hardness (Mohs) |

Features |

| Zirconia Balls | ≥9.0 | Super wear-resistance, without any impurity, corrosion & high temperature resistance. |

| Stainless Steel Balls | ≥6.0 | Wear-resistant, general corrsion resistance, high temperature resistance. |

| Agate Balls | ≥7.0 | Super wear-resistance, used for medicine,food and other materials which can not be contaminated with metal, corrosion, and high temperature resistance. |

| Alumina Balls | ≥8.5 | Wear-resistant, corrsion resistance and high temperature resistance. |

| Tungsten Carbide Balls | ≥9.0 | Super wear-resistance, without any impurity, corrosion & high temperature resistance. |

| Matching Solutions for Mill Jars & Balls | |||||

| Items | Agate Balls | Alumina Balls | Stainless Steel Balls | Zirconia Balls | Tungsten Carbide Balls |

| Agate Mill jar | √ | ||||

| Corundum Mill Jar | ▲ | √ | ▲ | ||

| Stainless Steel Mill Jar | √ | ||||

| Zirconia Mill Jar | ▲ | √ | |||

| Nylon Mill Jar | ▲ | √ | |||

| PTFE Mill Jar | √ | ▲ | |||

| Polyurethane Mill Jar | √ | ▲ | |||

| Tungsten Carbide Mill Jar | ▲ | √ | |||

| √ means: most suitable ▲ means: suitable | |||||