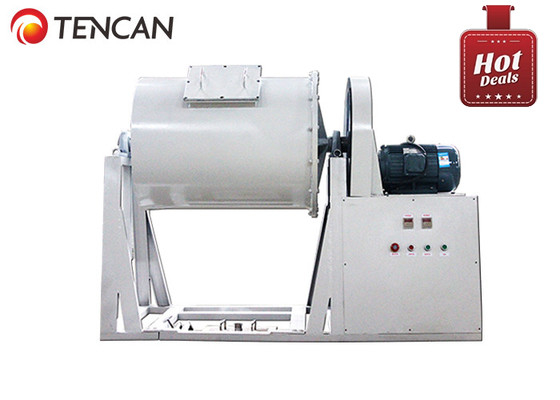

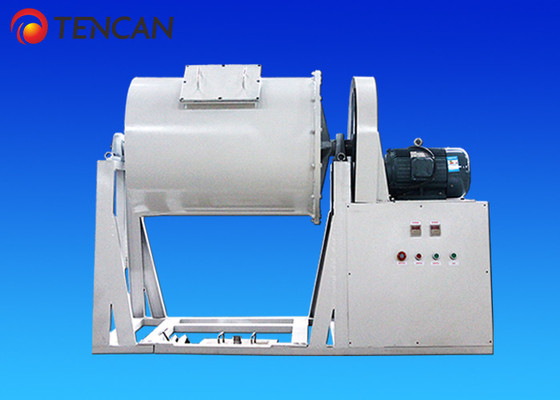

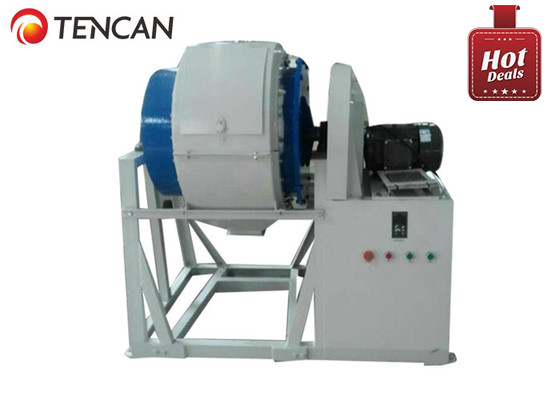

380V 100L 400 Mesh Powder Ball Mill Grinding Machine

Product Details:

| Place of Origin: | Hunan, China |

| Brand Name: | TENCAN |

| Certification: | CE ISO |

| Model Number: | QM-100 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plywood Case+Foam |

| Delivery Time: | 15-25 working days after getting full payment |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 220 sets per month |

|

Detail Information |

|||

| Product Name: | Light Roll Ball Milling Machine | Model No.: | QM-100 |

|---|---|---|---|

| Voltage: | 380V-50Hz | Power: | 7.5KW |

| Rotation Speed: | 20-50 RPM | Speed Control: | Frequency Control |

| Total Volume: | 100L | Max Capacity: | 33.0L |

| Highlight: | 400 Mesh Powder Ball Mill,100L Powder Ball Mill,380V Powder Ball Mill |

||

Product Description

QM-100L Laboratory Ball Mill - Precision Grinding Machine for 200-400 Mesh Powder Production

Overview

The China Tencan QM-100L Ball Mill is a high-performance grinding machine designed for ultra-fine powder processing in laboratory and small-batch production environments. With an optimized 200-400 mesh output range, this machine ensures uniform particle distribution and high grinding efficiency, making it ideal for R&D, material science, and industrial applications.

![]()

![]()

![]()

Key Features

✔ Precision Grinding – Produces 200-400 mesh (micrometer-scale) powders with consistent particle size

✔ Multi-Material Compatibility – Suitable for electronic, magnetic, pharmaceutical, ceramic, and metal powders

✔ Wet & Dry Grinding – Supports both methods for versatile material processing

✔ Automated Operation – Timing control panel with pause & cumulative timing functions

✔ Anti-Contamination Design – Optional polyurethane, zirconia, or stainless steel liners for purity-critical applications

✔ High Efficiency & Low Noise – Smooth operation with minimal energy consumption

Working Principle

The QM-100L uses rotational force to lift grinding media (balls) and materials, which then cascade down, generating impact, friction, and shear forces for ultra-fine particle reduction. The inclined-flow movement ensures uniform grinding and optimal dispersion.

Applications

Want to Know more details about this product

Similar Products