Low Energy Consumption Ultra Fine Grinding Machine Zinc Oxide Wet Turbine Cell Mill

Product Details:

| Place of Origin: | China |

| Brand Name: | TENCAN |

| Certification: | CE |

| Model Number: | TCM-1000 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Unit |

|---|---|

| Price: | negotiable |

| Packaging Details: | Plywood Case |

| Delivery Time: | With 2-3 months of working days after payment |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 30 units per month |

|

Detail Information |

|||

| Product Name: | Turbine Cell Mill | Model: | TCM-1000 |

|---|---|---|---|

| Power: | 110KW | Capacity: | 1.5-2.5T/H |

| Fineness (2:μm): | D60-D98 | Grinding Cost: | USD0.04-USD1.06/TON |

| Solid Content: | 50-70% | Power Consumption: | 36-115KW/T/H |

| Highlight: | 110 KW Ultra Fine Grinding Machine,Zinc Oxide Ultra Fine Grinding Machine,Turbine Cell Ultra Fine Grinding Machine |

||

Product Description

China Tencan TCM-1000 1.5-2.5T/H Low Energy Consumption Zinc Oxide Wet Milling Ultrafine Grinder, Turbine Cell Mill

1. Technical Data of Turbine Cell Mill

| Model |

Power (KW) |

2μm Fineness |

Solid Content(%) |

Capacity (ton/h) |

Power Consumption (KW/T/H) |

Grinding Cost (USD/T) |

| TCM-200 | 30 | D60-D98 | 50-70 | 0.05-0.2 | 38-155 | 0.18-0.82 |

| TCM-500 | 75 | D60-D98 | 50-70 | 1-1.5 | 35-105 | 0.04-1.06 |

| TCM-1000 | 11O | D60-D98 | 50-70 | 1.5-2.5 | 36-115 | 0.23-0.88 |

| TCM-1500 | 160 | D60-D98 | 50-70 | 1.8-3 | 37-124 | 0.28-0.79 |

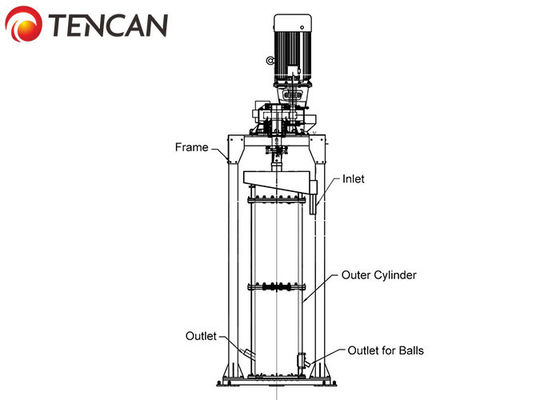

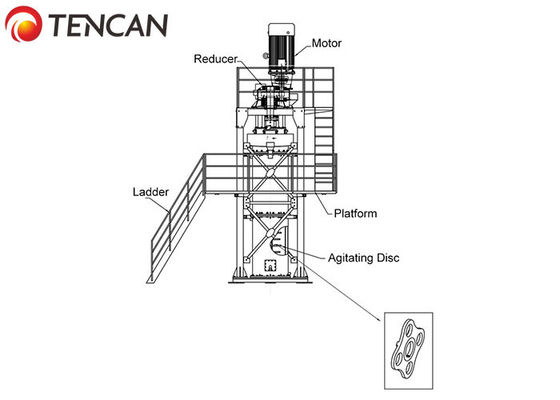

2. Overview of Cell Mill

Cell mill is a new type of mixing & wet milling machine that integrates gravity and fluidization technologies. It uses the rotating kinetic energy of the multi-stage alloy mixing plate to make the grinding medium balls filled in the grinding cavity generate orbital motion. Collision and shearing realize grinding process. The mixture of medium and slurry in the grinding chamber produces high-energy motion, and the medium and the material form a vortex, and the material particles collide and contact each other, thereby generating shear and squeezing forces between the particles, forming an ideal fine grinding process. Fluidization technology means that the stirring speed becomes much higher, which is enough to distribute the grinding media in various densities throughout the slurry, forcing particles to come into contact with the grinding media in all directions, and the materials are completely and effectively ground. The core of the cell mill and process configuration design is to maximize taste of the material and improve energy efficiency. Based on the above two ultra-fine grinding technologies, China Tencan can provide the best and customized equipment solutions to meet production process according to user’s requirements.

3. Application Fields

mica, talc, graphite, rare earth, lithium iron phosphate, zinc oxide, aluminum oxide, aluminum hydroxide, magnesium hydroxide, brucite, bentonite, kaolin, sulfur, calcium carbonate, coal water slurry, barite, fly ash, titanium dioxide, ferrite, magnetic ferrite, pigments and other non-metallic minerals.

4. Technology Advantages of Cell Mill

Cell mill is a large kind of wet ultrafine grinder independently developed by China Tencan. Considering in view of technical point, purpose of the desired solution is to minimize the total cost of fine powder particle grinding, improve taste of material and enhance energy efficiency, realize continuous production process, so as to reduce investment cost for customers maximally and meet requirements of industries and customers, exceed customers’ expectations continuously while meeting product requirements. Obviously, cell mill has many advantages in the following terms:

- Gravity and fluidization technology are integrated.

- Multi-stage alloy turbine disk structure, saving cooling device, reducing the shearing effect of medium and slurry on turbine disk and liner.

- Small footprint, vertical installation, lower feeding, upper discharging. Fast and convenient for installation and maintenance.

- high milling efficiency, low energy consumption, no wastes emissions.

- Adjusting the feed size can obtain different products in different specifications, fineness of the feed material is is required to be within 45μm-200μm.

5. Technical Characteristics

Fully automatic continuous production, high efficiency, low energy consumption, fineness from 0.5-5μm can be adjustable, narrow particle size distribution, easy to startup with load, and shorten process path.

6. Particle Size Distribution

Cell mill has a good particle size distribution range, it is not difficult to find in the below diagram that Its particle size distribution range is so narrow under 1μm, which verifies that efficiency and fineness of cell mill are always much better than other mills. Fineness of the cell mill varies with different characteristics of the ore, but its overall particle size can be controlled within a range of 0.5-15μm. We can carry out detailed experiments to help customers to determine the production process with best performance.

![]()

7. Cases of Process Plant

A. Single-stage grinding process

It is a very economical fine grinding process. Such a production line composed of one cell mill can grind products under 2μm ≤ D92 at a time.

![]()

B, Multiple-stage grinding process

Multiple-stage grinding process line consists of 2-3 sets of cell mills which are connected into a production line for grinding ore, where you can add media balls in different diameters, different specifications, and different specific gravity in each stage of the cell mill, you can grind to obtain products with diameter of 2μm≥D98 at a time. The multi-stage grinding process has characteristics of flexible changes, it is easy to produce D60 and D90 products without adding any other equipment, which can be changed from series mode to parallel mode.

![]()

C. Multi-stage mixing process

If you need to grind high-strength and large sized particles, you are suggested to use spiral cell mill for pre-grinding, where large sized particles of materials can be effectively crushed by strong impact and collision of the steel balls based on its gravity grinding technology. The multi-stage mixing process can better show its excellent grinding performance for grinding high-strength particles.

![]()